STRUX® STUDS

Outperforming Every Other Drive System

Stronger, More Reliable Fastening Solutions

STRUX® Stud Benefits

FEATURES

● Heat treated to SAE grades, ISO classes, or your own specifications

● Displacement lobes for secure fastening

● Ideal for joining dissimilar materials, pre-coated sheets, or high-strength thin sheet materials where welding is impossible or undesirable

● Unlike spot welding, joints can be created in-die with clinch fasteners and automated installation equipment

● Can be installed after painting or coating without aesthetic damage

● Easy installation and simple visual inspection

APPLICATIONS

VARIATIONS

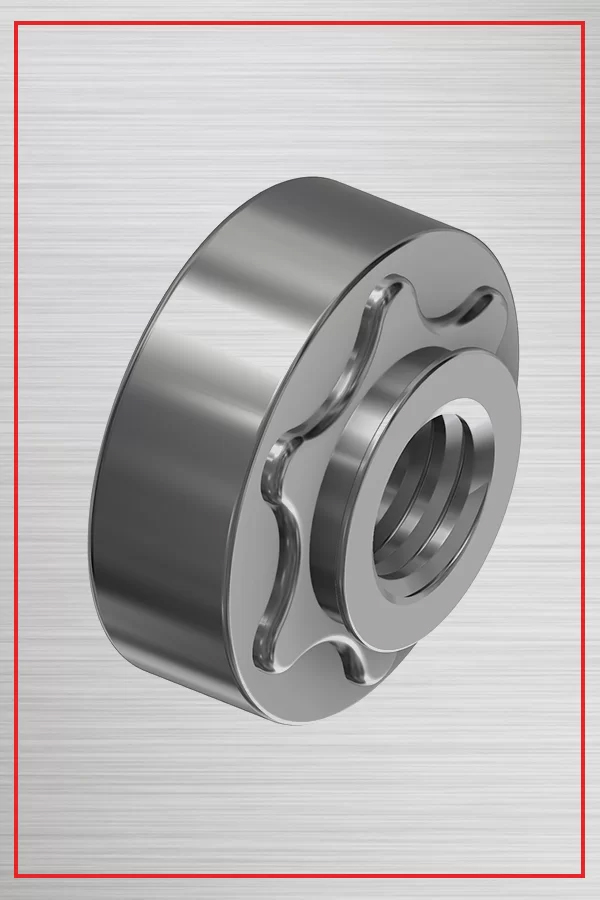

STRUX® Stud

• May replace larger diameter, conventional weld or other non-heat treated studs

• Resist push-out and rotation during service

• Eliminates hazardous welding operations and provides a cleaner appearance than welded fasteners

• Improved centerline-to-centerline tolerances compared to weld studs

• Lowers in-place costs and maximizes assembly flexibility

• No distortion due to excessive heat and increased production rates when using progressive dies

• Improved product and joint integrity

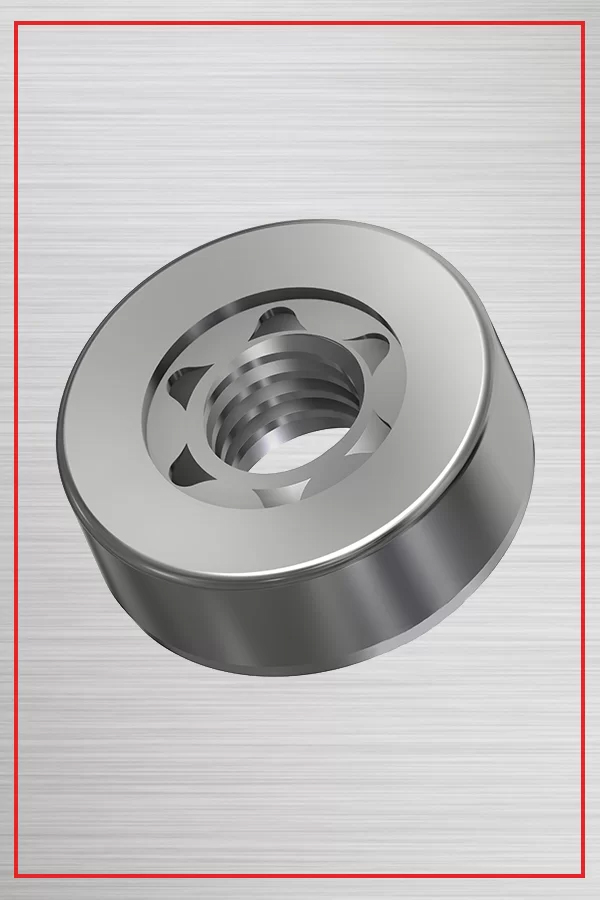

STRUX® Nut

• May replace larger diameter, conventional weld or other non-heat treated nuts

• Resist push-out and rotation during service

• Eliminates hazardous welding operations and provides a cleaner appearance than welded fasteners

• Improved centerline-to-centerline tolerances compared to weld nuts

• Lowers in-place costs and maximizes assembly flexibility

• Cross-threading and other problems caused by coated or painted threads can be prevented

• No distortion due to excessive heat and increased production rates when using progressive dies

• Improved product and joint integrity

PREVALOCK™

• Allows the engaging bolt to be started before the locking action begins, assuring fast, easy installation in addition to increased product integrity

•Increased resistance to vibration loosening, which helps the joint to remain secure

STRUXTITE® Nut

• Use in conjunction with Taptite® thread forming fastener

•Prevent cross-threading and other problems caused by coated or painted threads